When choosing exterior signage that must withstand harsh outdoor conditions, one common question arises: Do photopolymer signs fade or yellow over time? The short, confident answer is no—photopolymer signs are highly durable and do not suffer from fading or yellowing like some other materials, such as certain 3D printed signs. This makes photopolymer signage a solid choice for long-lasting, weather-resistant exterior applications.

Do Photopolymer Signs Fade Outdoors? Here’s The Truth

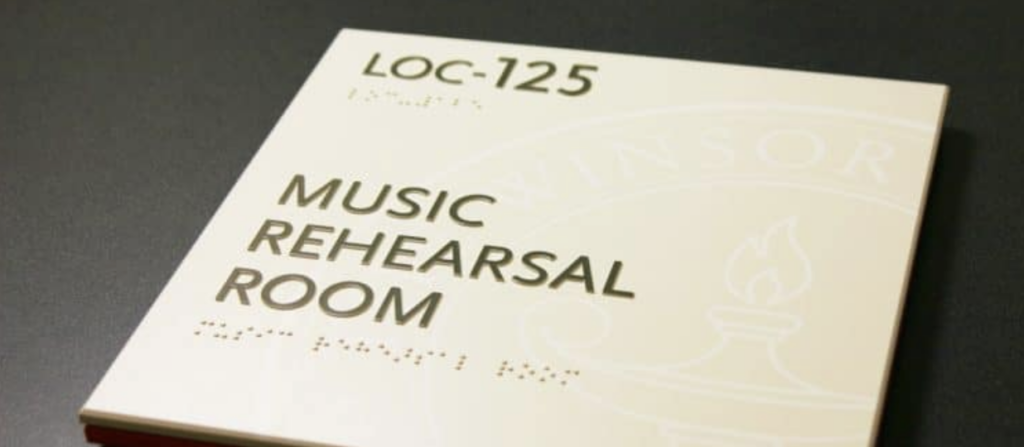

Photopolymer signage is created through a specialized 5-step process. Rather than layering colored ink repeatedly with a 3D printer—which leads to delamination and material breakdown after extended UV and weather exposure—photopolymer signs rely on a UV exposure method. A film negative is placed over a photosensitive polymer sheet, exposed to UV light, and then the unexposed areas are washed away. This leaves the characters, braille, or numbers, and an optional pictogram that is integral to the material itself, not simply surface-printed or layered.

Because the text and graphics are locked within the solid polymer structure, and because the material itself resists UV degradation, photopolymer signs maintain clarity and color without fading or yellowing even after long-term exposure to sun, rain, humidity, and cold.

How Does The 5-step UV Exposure Process Ensure Photopolymer Signs Resist Fading?

The 5-step UV exposure process ensures photopolymer signs resist fading and yellowing by fundamentally integrating the image into the polymer material itself through controlled UV curing.

Here’s how it works:

- Film Negative and Design Transfer: A film negative of the design is placed on top of a photosensitive photopolymer sheet. This allows precise areas to be selectively exposed to UV light.

- UV Light Exposure: The polymer sheet is exposed to UV light through the film negative. The UV light hardens (cures) the exposed areas of the polymer, creating a solid, durable raised image.

- Washing Away Unexposed Polymer: Areas not exposed to UV light remain soft and are then washed away, leaving the hardened design raised from the surface. This embeds the text and graphics physically into the polymer structure rather than simply printing them on the surface.

- Final UV Curing: A final UV exposure step ensures complete curing of the photopolymer material, stabilizing its chemical and physical properties.

- Sealing and Finishing: After curing, the sign is often sealed with a UV-resistant topcoat, which acts as a protective barrier against environmental damage.

Because the color and shape are formed as an integral part of the material through UV curing—rather than relying on layered inks or surface coatings—photopolymer signs have strong resistance against UV degradation mechanisms that cause fading and yellowing. The polymer structure remains chemically stable, and additives like UV stabilizers in the material help prevent oxidation and breakdown from sunlight exposure.

This meticulous curing process produces signage that withstands sun, rain, humidity, and temperature extremes for 10 years or more without losing clarity or color vibrancy, as demonstrated by accelerated weathering tests comparing photopolymer signs favorably against other methods like 3D printed signs reliant on surface inks. In summary, the 5-step UV exposure process locks the image into a durable polymer matrix through selective UV curing and uses finishing steps to protect the sign from UV damage, ensuring photopolymer signs do not fade or yellow outdoors.

Photopolymer vs. 3D Printed Signs: The Accelerated Weathering Test

Accelerated weathering tests that simulate 10 years of outdoor exposure have clearly demonstrated the superior durability of photopolymer signs. In such tests, 3D printed signs—where an ink-based 3D printer repeatedly deposits color on raised surfaces—start to chip, delaminate, and degrade significantly after just 98.3 days under accelerated conditions analogous to a decade outdoors. In contrast, photopolymer signs show remarkable resilience, maintaining their raised images, color integrity, and braille quality without damage.

Ensure your outdoor signage stands the test of time with Nova Polymers’ exterior-grade photopolymer signs. Durable, moisture-resistant, and visually striking, our Novacryl® EX™ Series is engineered for high-humidity and harsh weather environments. Ready to elevate your architectural signage with long-lasting, ADA-compliant solutions? Contact Nova Polymers today for expert guidance and any questions you have about our innovative photopolymer materials.

The restroom sign is a 3D printing sign, versus NovAcryl EX.

Advantages of Photopolymer Signs for Outdoor Use

- Longevity and Durability: Photopolymer signs withstand outdoor elements such as sunlight, moisture, and temperature swings without yellowing or fading.

- Resistant to Physical Damage: The raised lettering and graphics are integral to the sign face, making them difficult to chip, peel, or vandalize.

- Weatherproof: Tested to last well beyond 10 years in simulated outdoor climates with rain, sun, and humidity.

- Tactile and Compliant: Ideal for ADA signage with hardwearing braille that remains intact despite heavy tactile use.

Choosing Photopolymer for Your Exterior Signs

For businesses, public buildings, schools, and facilities that require signs to retain a professional appearance and comply with accessibility standards over the long haul, photopolymer signage is an excellent investment. Unlike cheaper 3D printed or surface-painted signs, photopolymers’ robust manufacturing process ensures the graphic content and tactile features last a decade or more outdoors with minimal maintenance.

If your priority is a sign that won’t fade, yellow, or chip, photopolymer answers the question: Do photopolymer signs fade? No, they do not. Their superior resistance to UV and weather damage, proven by accelerated testing, makes them a wise and durable choice for exterior signage.

By understanding the key differences in production and material behavior, it’s clear that photopolymer signage offers unmatched durability and aesthetic retention outdoors compared to many 3D printed sign alternatives. For reliable, long-term exterior identification, photopolymer signs stand the test of time without fading or yellowing.