Being a sign is no easy feat. Whether new or existing, signs often need extra care to ensure they last as long as possible. For new signs, this might mean adding a protective coating during manufacturing, while older signs might require periodic touch-ups to maintain their appearance. One key component in this process is using clear photopolymer technology, which can greatly enhance the longevity and durability of your signs.

Why Clear Photopolymer Matters

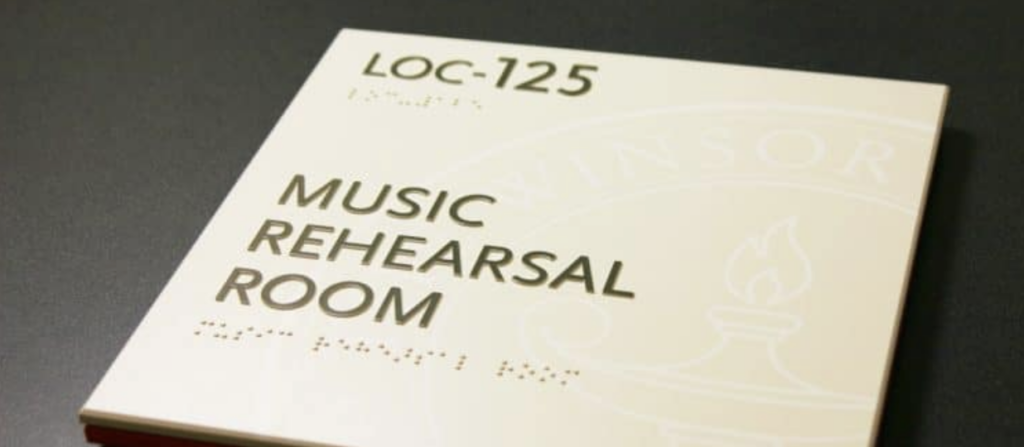

Clear photopolymer plays a crucial role in the durability and appearance of signs. For example, NovAcryl PT Series Clear Based Photopolymer is designed for interior use and offers resilience and shatterproof qualities. It’s essential to apply a clear coat over photopolymer signs to protect the design and ensure long-lasting quality. Below, we’ll explore the key benefits of using clear photopolymer for ADA sign substrates and why it’s a smart choice for fabricators, designers, and facility managers

- Versatile Aesthetics

One of the primary reasons clear photopolymer is preferred in ADA sign production is its versatility in design. Because it’s transparent, it can be back-painted to match any color scheme, giving fabricators greater creative control over the final look. The clear nature of the substrate allows for the precise application of custom colors, textures, or even patterns while ensuring the raised tactile elements and braille remain ADA-compliant. This flexibility ensures that signs can be customized to complement the design of any building, from modern office complexes to historical landmarks.

- Durable and Impact-Resistant

Durability is a key consideration for ADA signs, especially those placed in high-traffic areas. Clear photopolymer substrates are known for their toughness and long-lasting properties. They are highly resistant to wear and tear, making them ideal for environments such as hospitals, schools, airports, and commercial buildings. The material is also impact-resistant, ensuring that the raised lettering and braille remain intact even under heavy usage or accidental impacts.

- Seamless Braille and Tactile Lettering Integration

Photopolymer substrates provide a seamless solution for integrating tactile lettering and braille into the sign. The photopolymer process involves creating raised elements in a single piece, which eliminates the need for glue or adhesive layers that could deteriorate over time. This one-piece construction not only increases the longevity of the sign but also ensures better readability and compliance with ADA standards. Clear photopolymer provides a crisp, precise formation of raised elements, which is crucial for maintaining the integrity of tactile components.

- Eco-Friendly Option

Clear photopolymer is also considered an eco-friendly substrate option. Many manufacturers have developed environmentally conscious processes for producing photopolymer materials, such as water-washable photopolymers that don’t require harmful chemicals during processing. Choosing a clear photopolymer for ADA signage can contribute to a building’s sustainability goals, especially in projects seeking LEED (Leadership in Energy and Environmental Design) certification or other green building standards.

- Cost-Effective Production

Clear photopolymer offers a cost-effective solution for ADA-compliant signage, especially in larger production runs. The process allows for efficient production of tactile and braille signs in high volumes without sacrificing quality. Using a single substrate that can be back-painted to achieve the desired appearance reduces the need for additional layers or materials, streamlining the manufacturing process and reducing overall production costs.

- High UV and Chemical Resistance

ADA signs made from clear photopolymer substrates are highly resistant to UV light and chemical exposure, which makes them ideal for both indoor and outdoor applications. Whether installed in a sun-exposed outdoor area or in a chemical-prone environment like laboratories or industrial facilities, clear photopolymer signs retain their appearance and functionality. The material’s resistance to fading and discoloration ensures that the signage remains visually appealing and compliant for years to come.

- Easy Maintenance

In addition to their durability, clear photopolymer ADA signs are easy to maintain. The substrate’s smooth surface makes it simple to clean, ensuring the raised elements stay legible and the sign remains visually appealing. This is especially important in environments where cleanliness and sanitation are a priority, such as healthcare facilities and food processing plants.

Clear Photopolymer: The Ideal Substrate for ADA-Compliant Signage

Clear photopolymer has become a go-to substrate for fabricators creating ADA-compliant signage thanks to its versatile aesthetics, durability, and ease of production. Its ability to meet ADA standards while offering creative freedom makes it an excellent choice for any project where both compliance and design matter. Additionally, clear photopolymer’s eco-friendliness, cost-effectiveness, and resilience against UV and chemical exposure make it a smart, long-term solution for facilities and architects looking to enhance their signage.

When selecting the right materials for ADA signage, clear photopolymer provides the perfect balance of form, function, and durability—making it an essential choice for anyone involved in the design, fabrication, or installation of ADA signs.