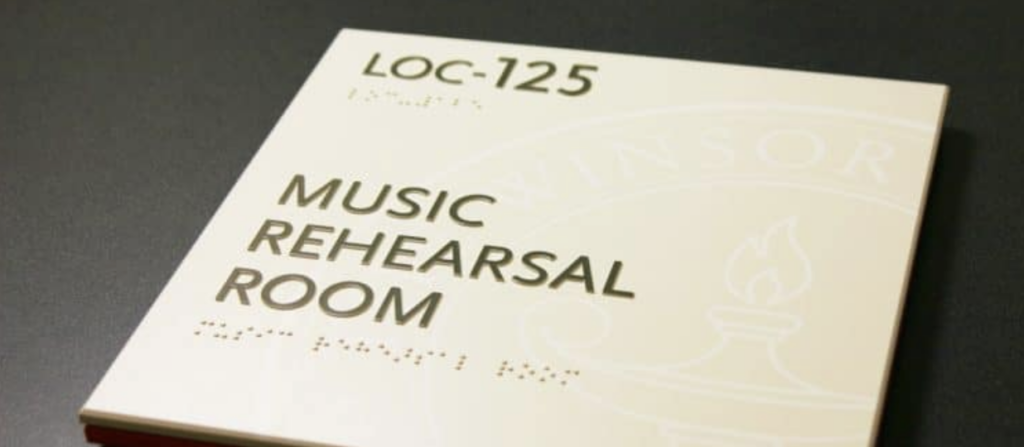

As sign fabricators, we understand that the process of creating signs is intricate, requiring precision, accuracy, and meticulous attention to detail. With all the focus on precision and detail, sign fabricators should review their current processes to identify areas for improvement. One common area for enhancement when producing photopolymer signage is optimizing washout times. Many don’t realize how crucial washout times are for photopolymer signage and how having the right washout brush is key for fabricators to speed up these times.

What Happens When You Don’t Have the Right Washout Brush?

Washout units and processors often utilize washout brushes to remove the unhardened polymer from the surface of the plate. These brushes are typically composed of single spiral filaments locked onto a cylindrical support to reach all areas of the polymer. The washout process occurs through the mechanical abrasion caused by the bristles of the washout brush as they come into contact with the surface of the plate. When the washout is complete, all the unexposed polymer should be washed away, leaving only the exposed areas ready for drying. To check whether a plate is properly washed out, run your fingernail along the edges to ensure no polymer is left behind.

The Importance of Optimizing Washout Times

One crucial aspect to understand about the washout process is that washout times should not be overly prolonged. Generally, five minutes is sufficient to wash all your products. A proper washout brush will effectively scrub the unexposed polymer out neatly and efficiently within this time frame. If your washout time exceeds five minutes, there may be an issue with the washout brush you are currently using. A normal brush that lacks excessive moisture capacity is unlikely to wash off excess polymer effectively.

Keep in mind that brushes with medium or firm bristles can scratch and damage your plate, negatively impacting the final product. Excess polymer is also more likely to settle between the bristles of a regular washout brush due to the lubrication of water-based solutions. This excess polymer will harden, rendering the brush ineffective and more prone to deterioration.

To prevent these issues, it’s essential to have the right washout brush that optimizes your washout times and ensures effective use of your photopolymer materials. Not only will having the proper brush boost efficiency and improve washout performance, but it will also lower the risk of overwashing your photopolymer. With this in mind, we want to share our hidden secret to improve washout times for photopolymer material.

Finding The Right Washout Brush

If you fabricate exterior signage regularly, it is vital to have a washout brush that enhances the processing of exterior-grade photopolymer. Our EX washout brush is designed with high-quality, eco-friendly materials. Its main benefit is that it enhances the washout of non-exposed polymer material, ensuring your work is completed efficiently without waste and to your exact requirements. With this brush, you can reduce your washout times by 40% without any additional scrubbing. The EX washout brush also allows for a smoother, more uniform wash across photopolymer sheets compared to regular brushes.

Benefits of Our EX Washout Brush:

- Contains a larger number of bristles designed to optimize the cleaning experience

- Features softer bristles that align more closely to the pad

- Has increased moisture levels

- Provides enhanced capacity to absorb moisture with lower degrees of hardness

- Offers faster, better washout for exterior signs

- Dissolves polymer more effectively

- Experiences less clogging compared to standard brushes

- Has low viscosity to push photopolymer through the Airbrush system with minimal pressure

- Improves washout cleaning of Novacryl EX material

How to Extend the Life of Your Washout Brush

For optimal use and results, it is crucial to maintain the quality of your washout brush through regular cleaning. Here are five simple steps to help extend the life of your brush:

- Change water after 5-7 runs in a static tank setup.

- Set your processing tank water level to be 1/16th of an inch below the tips of the brush bristles.

- Establish an open flow system for the processing tank, where the intake water is split into hot and cold in an open setup. The drain valve should remain open to maintain a constant water level over the bristles at a temperature of 70-75°F.

- At the end of your shift or production day, drain the processing tank and wash down the brush bristles, processing tank sides, and tank bottom to remove all photopolymer residue.

- Add 2 cups of white vinegar to the filled processing tank water each production day to reduce the likelihood of polymer residue sticking to the brush bristles.

Key Takeaways

Sign fabricators must ensure they have the proper washout brush for efficient washout times and outcomes. Fabricators that utilize the right washout brush will be able to improve their washout times and boost productivity while saving time and money, enabling them to achieve greater success and profitability in the long run. Now is the ideal time for sign fabricators to assess and evaluate their current operations and workflow procedures to implement changes that enhance efficiency when manufacturing photopolymer signage.

Nova Polymers provides the finest equipment you need to improve your washout times and save both time and money. We are dedicated to helping you identify and resolve any issues in your production processes so your signage business can grow and prosper as you envision. For more information about our services, contact us today.