Has every architect or designer heard this discussion about ADA sign specifications before?

Architect: I am receiving complaints from my client, the building developer. She tells me that the signs we installed a few months ago are failing. People handling the signs are causing them to discolor, and pieces are falling off.

Fabricator: OK. That is a tough situation.

Architect: We planned this and specified heavier-duty materials. Were they used in the project?

Fabricator: Remember that we found a similar alternative that cut the cost by 5%.

Architect: How similar is it? It’s failing. I never asked you to change this specification. We clearly stated that we wanted more durable materials. You are going to have to replace them.

Fabricator: Well, it is a gray area.

This conversation is a common issue between architects and fabricators. Architects have it in their best interest to buy the best materials for a given context, even if it costs a little more. The price to the architect is much higher if the material fails than the small price savings to the client. This often results in contentious arguments to balance price and quality with the client.

Fabricators can have the opposite incentives. They have a better chance of getting the work in a bid by using less expensive but less durable materials, which is not always evident when the project is first built. They are not exposed to all the meetings with the client where these issues are hashed out. Many times, they have the best intentions, thinking that the alternatives are good enough for the context, but on the other hand, they do not feel responsible for the failure since they noted the alternative in their bid.

So, what is an architect or designer to do? There is no easy solution, but the best approach is to lock down the most important specifications before the bid process. These approaches particularly help strong fabricators, whom architects should want to encourage to succeed. These fabricators are reluctant to sacrifice quality for price.

The Importance of Clear ADA Sign Specifications

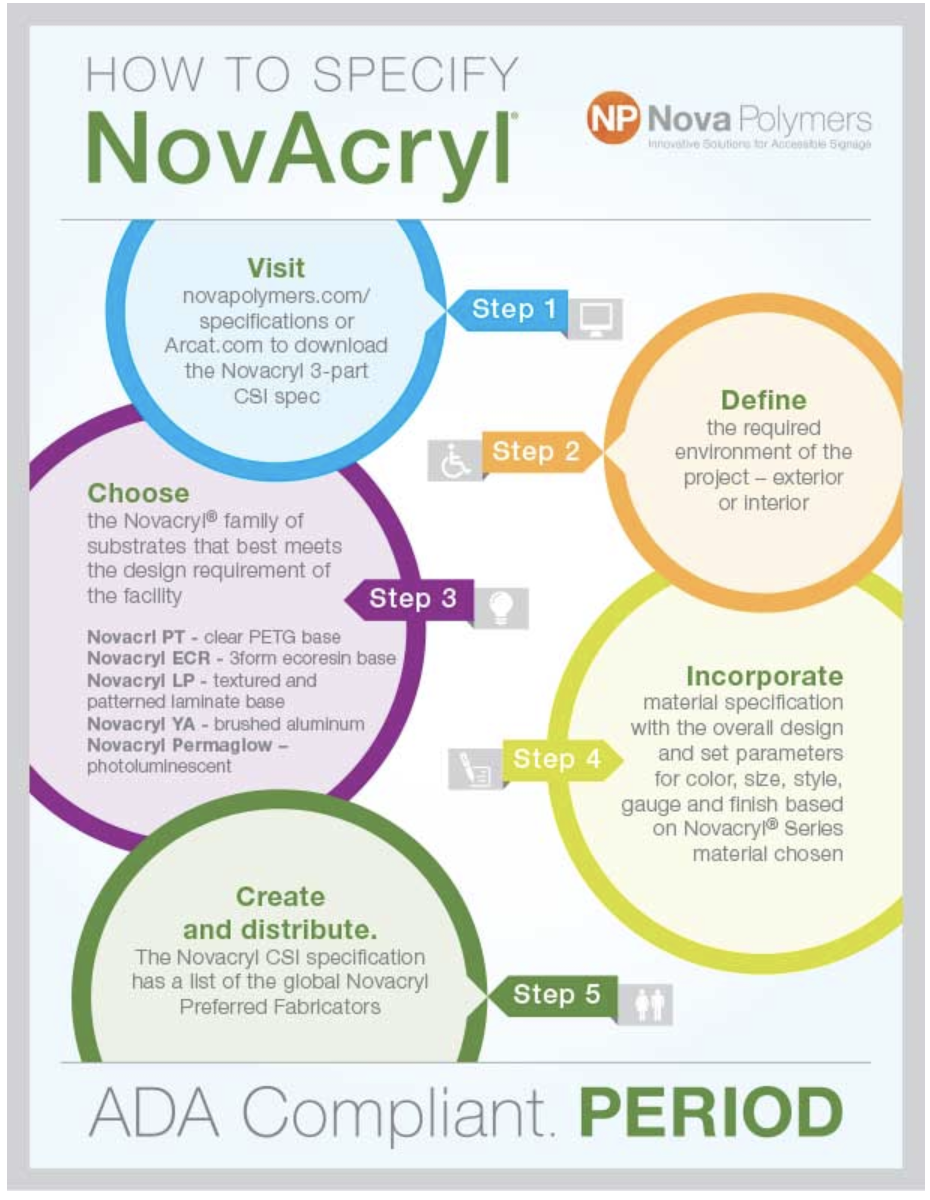

Having clear and precise ADA sign specifications is crucial for ensuring the success of your projects, especially those involving ADA-compliant signage. Tightening these specifications can help avoid misunderstandings, reduce costs, and improve overall project quality. Here are four effective strategies for tightening your specifications and ensuring your project runs smoothly

1. Tighten the Specification

Performance specifications are essential, particularly when negotiations regarding materials take place between fabricators, designers, and clients. However, there is often room for misinterpretation during the bidding process, leading to potential breakdowns. By tightening your ADA sign specifications and including specific materials and methodologies in your bidding documents, you can help maintain competitive bids without sacrificing quality.

2. Provide Reasons for Qualification

When crafting your specifications, particularly technical ones, include specific reasons for the choices made. This practice reinforces the importance of the ADA sign specifications and provides a clear rationale for fabricators. By requiring fabricators to justify any changes to the specifications, you encourage a deeper understanding of the project’s needs and promote accountability.

3. Have an Open Informational Meeting During the Bid Process

Before the final bid submission, consider holding an informational meeting to discuss the key elements of your ADA sign specifications. This meeting serves as an excellent platform for asking questions and addressing any concerns related to the specifications. Strong fabricators will appreciate this opportunity to engage in a detailed discussion about potential changes.

For negotiated bids, a formal meeting between the designer, client, and fabricator can significantly enhance communication and understanding. It allows everyone involved to clarify expectations and ensures that the specifications are fully understood and adhered to.

4. Assuring the Change

If a fabricator proposes a change during the bidding process, require them to provide a detailed explanation for the change. Additionally, consider implementing a warranty for one year if the specifications are based on durability. This one-year warranty provides ample time to assess the performance of any material changes.

Another effective strategy is to conduct a second performance punch list review three months after installation. This proactive approach ensures that any immediate issues are addressed quickly, safeguarding the quality and compliance of your ADA sign specifications.

Project Success and Compliance with Better ADA Sign Specifications

By tightening your ADA sign specifications using these strategies, you can significantly enhance project success, reduce costs, and ensure compliance. Clear and detailed specifications lead to better communication among all parties involved, resulting in high-quality signage that meets the necessary regulations and serves its purpose effectively.