NovAcryl photopolymer signage has revolutionized the production of ADA-compliant signs, offering durability, efficiency, and high-quality results. In this blog, we’ll explore the straightforward process of creating NovAcryl photopolymer signage and why it might be the right choice for your sign-making business.

Understanding NovAcryl Photopolymer Signage

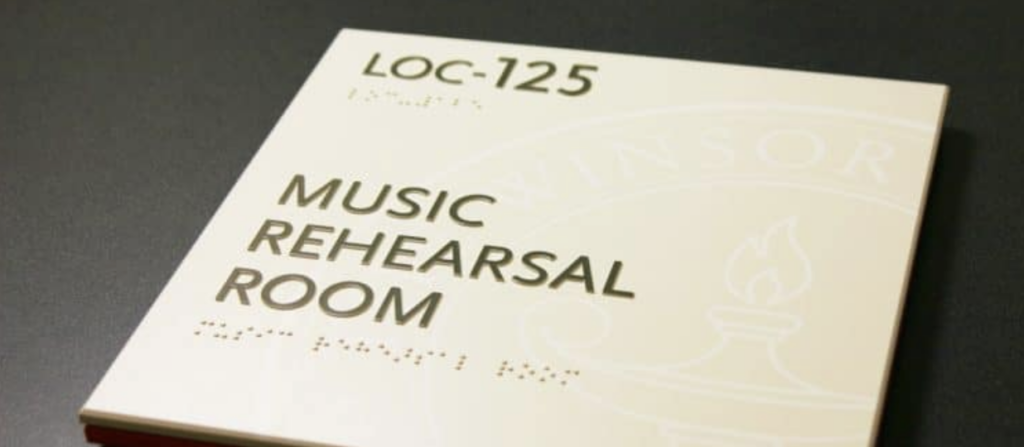

NovAcryl photopolymer signage is renowned for its longevity and compliance with ADA standards. Nova Polymers, the industry leader in this technology, has developed a simple yet effective 5-step process for creating these signs.

The 5-Step Process for NovAcryl Photopolymer Signage

- Contact With Film Negative: Place a high-density film negative on the photopolymer sheet.

- UV Light Exposure: Expose the material to UV lamps, which pass through clear areas of the negative.

- Washout: Rinse with plain tap water to remove unexposed photopolymer.

- Drying: Evaporate any remaining moisture from the sheet.

- Post Exposure: A final UV exposure is needed to cure and harden the photopolymer fully.

Key Components for Processing NovAcryl Photopolymer Signage

While the process is straightforward, there are essential elements to consider:

- Painting Equipment: A paint booth is crucial as all NovAcryl photopolymer signage requires a top coat or clear coat.

- Photopolymer Processor: This equipment is central to the production process.

- Design Software: Nova Polymers offers software to minimize errors and material waste.

Advantages of Novacryl Photopolymer Signage Production

- Scalability: The process allows for the efficient mass production of ADA signs.

- Cost-Efficiency: With proper equipment, the production is streamlined and cost-effective.

High Output: A typical shop can produce around 400 8″x8″ signs in one workday.

Is NovAcryl Photopolymer Signage Right for Your Business?

Processing NovAcryl photopolymer signage is not overly complex; it requires specific equipment and skills. Consider these factors:

- Investment: Evaluate if the initial equipment costs align with your business goals.

- Demand: Ensure you have sufficient demand for ADA-compliant signage.

- Training: Nova Polymers offers support and training to help you master the process.

Watch our training video on How To Process Novacryl Photopolymer to learn more about how photopolymer signs are made.

Contact Nova Polymers

NovAcryl photopolymer signage offers a reliable, efficient method for producing high-quality ADA-compliant signs. By understanding the process and required components, you can determine if bringing NovAcryl photopolymer signage production in-house is the right move for your business. Contact Nova Polymers to learn more.