Photopolymer technology is transforming the way companies create visually stunning, durable, and intricate award displays. For Bold Rock Hard Cider, a cidery based in the picturesque Blue Ridge Mountains of Virginia, showcasing their award-winning reputation was key. With the help of Acorn Sign Graphics and Mountain Laurel Studios, Bold Rock turned to creative applications of photopolymer to reproduce their award medals in a way that reflects both the quality and craftsmanship of their ciders.

Applications of Photopolymer: Bringing Awards to Life

Bold Rock’s hard cider, crafted from local apples, has garnered numerous awards in recent years. To celebrate these achievements, Bold Rock wanted to recreate these award medals and display them throughout their facilities. Using photopolymer, Acorn Sign Graphics produced exact replicas of Bold Rock’s award medals. Mountain Laurel Studios meticulously redrew the medals in Illustrator from physical references, capturing every detail. Acorn then translated these digital designs into tangible, beautifully finished medals using Novacryl photopolymer.

Construction and Specifications: Photopolymer at Work

Each replica medal was crafted using specific construction specs and high-quality materials to ensure durability and a close match to the originals. Here’s a breakdown of how photopolymer was used in this project:

- Material: 1/8″ Novacryl photopolymer

- Surface Treatment: Painted for an authentic medal appearance

- Shaping: Routed with a CNC router for precision

- Mounting: Holes routed for easy mounting across different display locations

The meticulous construction process allowed Acorn Sign Graphics to produce medals that look and feel like the originals, showcasing the creative applications of photopolymer technology.

Step-by-Step Process: From Digital Design to Finished Product

- Film Negative Creation: The design process began with a film negative, created using Oyo Thermal Film. This negative served as the basis for the photopolymer’s exposure and shape.

- Photopolymer Processing: Using the Novacryl PT Series photopolymer, the film negative was exposed and washed out, leaving a raised design on the photopolymer that matched the award details precisely.

- Routing and Shaping: The photopolymer was then processed and routed to its final shape, maintaining the fine edges and details necessary to accurately replicate the medals.

- Finishing Touches: Finally, the processed medal replicas were surface painted, cut, and tipped to achieve the polished, high-quality finish Bold Rock wanted.

Expanding the Creative Applications of Photopolymer

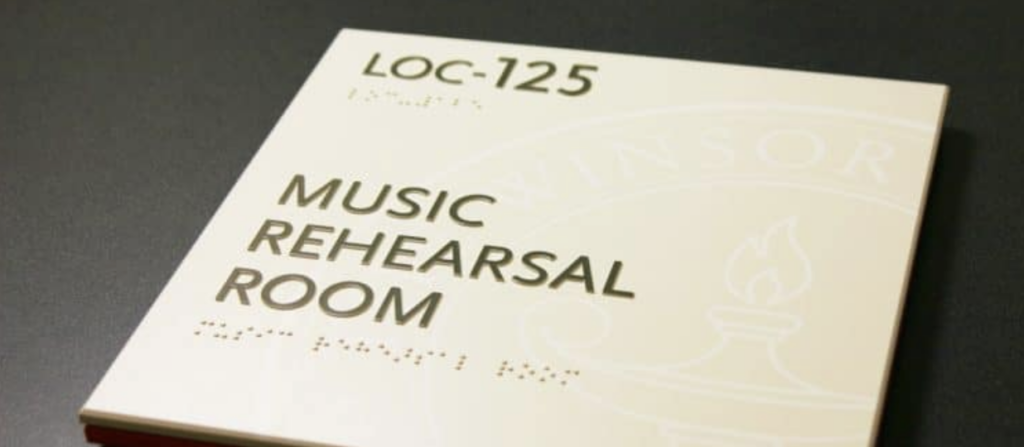

Photopolymer technology opens up new possibilities for custom signage and display pieces, as illustrated by this project. While it’s traditionally used for ADA signage, the creative applications of photopolymer extend to diverse projects like award reproductions, branded displays, and intricate artwork. By using photopolymer, Acorn Sign Graphics was able to produce awards that are both eye-catching and durable, perfect for long-term display in Bold Rock’s tasting rooms and production areas.

Beyond Awards: Photopolymer in Custom Signage and Design

The versatility of Novacryl photopolymer makes it an ideal material for projects that demand precision, durability, and an attractive finish. From ADA compliant signs to branded awards, photopolymer is changing how businesses approach custom design. The material’s flexibility, coupled with its compatibility with various surface treatments and finishes, means it can adapt to countless creative applications.

If you’re inspired by the creative applications of photopolymer for projects beyond awards, reach out to learn more. Nova Polymers provides a wide range of photopolymer products designed to meet the unique needs of industries from architecture to branding. Start your next project with Nova Polymers and experience the power of photopolymer technology.