In signmaking, the adhesive to substrate matrix plays a pivotal role in ensuring the durability, functionality, and aesthetic appeal of signage. For sign shop owners, understanding this matrix is not just about choosing the right adhesive—it’s about reviewing all materials and processes to optimize performance while minimizing costs associated with failures or remakes. This blog explores the significance of the adhesive to substrate matrix and offers insights into how careful planning can save time and money.

Understanding the Adhesive to Substrate Matrix

The adhesive to substrate matrix refers to the relationship between the adhesive used and the substrate (material) it bonds with. Each material reacts differently based on its physical properties, environmental exposure, and adhesive compatibility. For example:

- Metals require adhesives that can handle significant thermal expansion and contraction.

- Plastics demand flexible adhesives due to their susceptibility to temperature-induced deformation.

- Aluminum Composite Materials (ACMs), commonly used in signage, need specially formulated adhesives to prevent bond-line read-through and maintain surface aesthetics.

By understanding these interactions, signmakers can select adhesives that ensure long-term performance under specific conditions.

Why Reviewing Materials and Processes is Essential

Failures in the field—such as delamination, cracking, or discoloration—can cost sign shops both time and money. Signs that fail often need to be remade, leading to wasted materials, labor, and potential damage to a shop’s reputation. To avoid these issues, it is crucial for sign shops to review all aspects of their materials and processes:

1. Material Compatibility:

- Ensure that adhesives are compatible with the substrate’s surface energy. High-energy surfaces allow better adhesion compared to low-energy surfaces like waxed or coated materials.

- Test for long-term performance under environmental stressors such as UV exposure or humidity.

2. Processing Procedures:

- Proper surface preparation is key. Cleaning, roughening, or pre-treating substrates (e.g., plasma treatment) can significantly enhance adhesion strength.

- Use adhesives designed for specific applications, such as low-exotherm adhesives for thin-gauge materials like ACMs.

3. Environmental Considerations:

- Outdoor signs face challenges like weathering and aging. Selecting UV-resistant adhesives can prevent degradation over time.

Benefits of Optimizing the Adhesive to Substrate Matrix

By carefully reviewing materials and processes within the adhesive to substrate matrix, sign shops can achieve several benefits:

- Enhanced Durability: Proper adhesive selection ensures signs stand up to environmental stresses without failure.

- Cost Savings: Reducing failures minimizes material waste and labor costs associated with remakes.

- Improved Aesthetics: Preventing issues like bond-line read-through maintains the visual appeal of signage.

- Customer Satisfaction: Reliable signs enhance customer trust and reduce complaints.

Practical Steps for Sign Shops

To fully leverage the adhesive to substrate matrix, sign shops should implement these best practices:

- Evaluate adhesion strength using standardized methods like ASTM D335.

- Test adhesives under real-world conditions to simulate environmental exposure.

- Work with adhesive manufacturers to identify products tailored for specific substrates and applications.

- Request technical support or design reviews from suppliers for complex projects.

- Educate employees on proper adhesive application techniques.

- Emphasize the importance of surface preparation in achieving optimal results.

- Periodically audit materials and procedures to ensure alignment with industry advancements.

- Stay updated on new adhesive technologies that offer improved performance or cost-efficiency.

Mastering the Adhesive to Substrate Matrix: Elevate Your Signmaking with Nova Polymers

The adhesive to substrate matrix is a critical consideration in signmaking that directly impacts performance, cost-efficiency, and customer satisfaction. By thoroughly reviewing materials and processes, sign shop owners can avoid costly failures while delivering high-quality products. Investing time in understanding this matrix is not just a technical necessity—it’s a strategic move that pays off in reliability, reputation, and revenue growth.

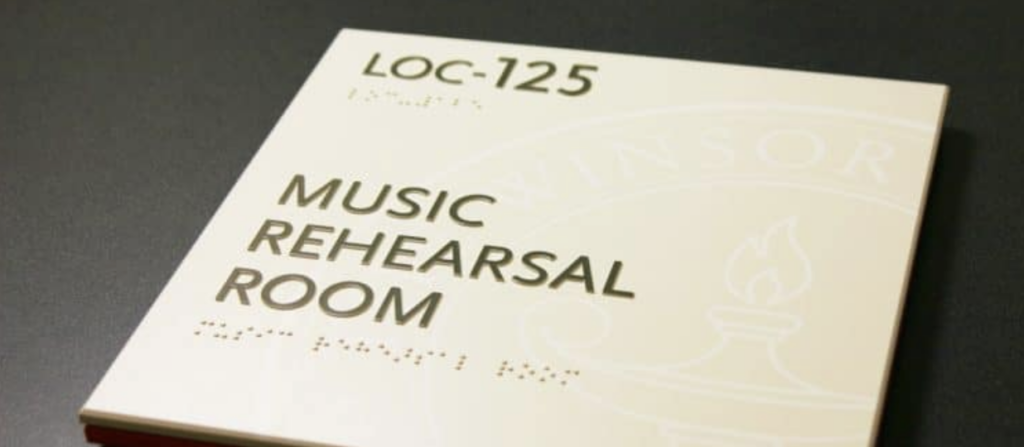

Looking for the perfect combination of signage substrates and adhesives for your ADA-compliant signs? Nova Polymers offers an unmatched selection of photopolymer materials, including our industry-leading Novacryl® line, paired with premium adhesives like 3M and tesa tapes.

Whether you’re designing sleek, modern signage with brushed aluminum finishes or crafting eco-friendly solutions with recycled content, Nova Polymers ensures durability, compliance, and creativity. Explore our diverse range of substrates and adhesives to streamline your fabrication process, reduce errors, and deliver high-quality results every time. Partner with Nova Polymers today to elevate your ADA signage projects!