When it comes to ADA signage manufacturing, few companies have the depth of experience that Bell Company brings to the table. Since 1946, and producing ADA compliant signage since the legislation was introduced in 1990, Bell Company has witnessed the evolution of the industry firsthand. Their secret to maintaining quality and efficiency? Nova Polymers’ photopolymer technology.

Three Decades of ADA Signage Innovation

Bell Company’s journey in the ADA signage industry spans 35 years—making them true pioneers in the field. Over those decades, they’ve tested countless materials and methods for producing tactile and braille signage. Through all those years of experience, one material has proven superior: photopolymer.

“Photopolymer is consistent, clean, and reliable,” states Tina Kirk from Bell Company, summarizing what matters most in high-volume ADA sign production. These three qualities—consistency, cleanliness, and reliability—are the foundation of their ability to deliver exceptional wayfinding solutions project after project.

The Speed of Photopolymer ADA Signage Production

In the sign manufacturing business, time is money. Bell Company has optimized their workflow to achieve remarkable efficiency using Nova Polymers‘ photopolymer system for ADA signage. The results speak for themselves: they can create a complete ADA-compliant sign, from initial concept to film negative to a finished, paint-ready product, in under 30 minutes.

This production speed doesn’t come at the expense of quality—in fact, it’s the quality of Nova Polymers’ photopolymer materials that enables such rapid turnaround times. The consistency of the material means less troubleshooting, fewer production errors, and more time spent fulfilling orders instead of fixing problems.

For businesses managing multiple ADA signage projects simultaneously, this efficiency translates directly to increased capacity, faster client delivery, and improved profitability.

Unmatched Detail in Tactile Signage Applications

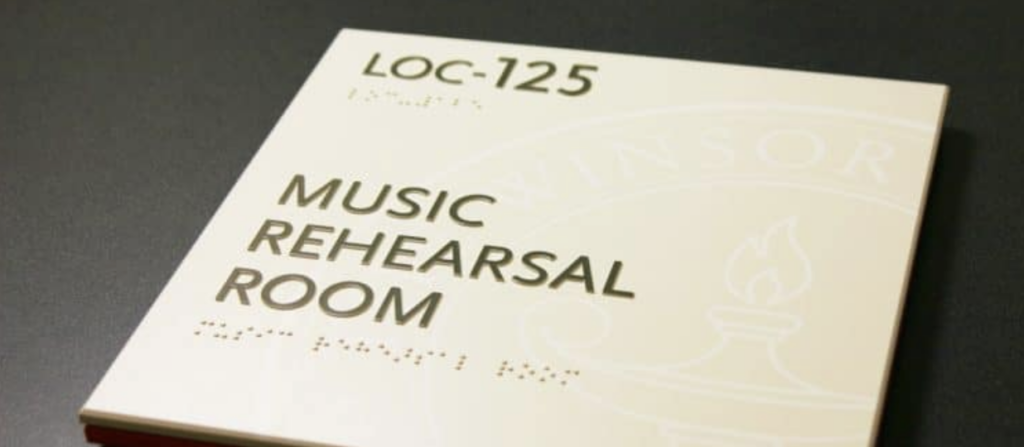

While speed matters, the ability to produce intricate, detailed ADA signage is equally critical. Bell Company regularly handles complex wayfinding projects requiring fine details, custom logos, and detailed maps—all of which must maintain perfect tactile quality for ADA compliance.

“Photopolymer holds raised fine lines, logos, and detailed maps unlike any other process,” Kirk explains. This capability sets Nova Polymers’ photopolymer technology apart from alternative methods that struggle with fine detail work.

Whether producing:

- Directional wayfinding signage with intricate campus maps

- Custom branded ADA signs incorporating corporate logos

- Detailed tactile graphics for accessibility applications

- Multi-element interior signage requiring precise specifications

Bell Company relies on Nova Polymers’ photopolymer to deliver the detail and precision their clients expect.

The Value of Expert Support in ADA Signage Manufacturing

With 79 years in business and 35 years specializing in ADA compliant signage, Bell Company has seen it all. Yet even experienced manufacturers benefit from having expert partners who can provide guidance, troubleshooting, and technical support.

“Having the Nova team and their years of experience on stand-by, should an issue arise, is priceless,” Kirk notes. She describes reaching out to Nova Polymers as “like having a paint specialist, production lead, and ADA consultant in your back pocket.”

This level of support is particularly valuable in the ADA signage industry, where regulatory requirements, material specifications, and production techniques all intersect. Nova Polymers doesn’t just sell photopolymer materials—they provide comprehensive expertise that helps manufacturers like Bell Company navigate challenges and optimize their processes.

Why Photopolymer Technology Leads the ADA Signage Market

Bell Company’s endorsement of photopolymer for ADA signage comes from decades of hands-on experience with alternative materials and methods. They’ve witnessed the evolution from early ADA signage techniques to today’s sophisticated photopolymer systems, and they’ve chosen to build their reputation on Nova Polymers’ patented technology.

The advantages of Nova Polymers’ NovAcryl Photopolymer for professional sign manufacturers include:

- Production consistency that eliminates guesswork and waste

- Clean processing that maintains workspace efficiency

- Material reliability that ensures predictable results

- Fine detail capability for complex tactile applications

- Speed and efficiency that maximizes production capacity

- Long-term durability for signage that lasts in any environment

Building on a Legacy of Quality ADA Signage

For Bell Company, choosing Nova Polymers wasn’t just about finding a material supplier—it was about partnering with a company that shares their commitment to excellence in ADA signage manufacturing. After 35 years in the ADA signage business, they understand that quality materials and reliable support are what separate successful manufacturers from the rest.

The combination of Nova Polymers’ proven photopolymer technology and responsive customer service has enabled Bell Company to maintain their reputation for quality while continuously improving efficiency and expanding capabilities.

Experience the Bell Company Standard with Nova Polymers

Bell Company’s three-and-a-half decades of ADA signage expertise demonstrate what’s possible when manufacturers invest in the best materials and partners. Their ability to produce detailed, compliant, beautiful signage in under 30 minutes showcases the power of Nova Polymers’ photopolymer system.

Whether you’re a long-established sign company like Bell or launching your ADA signage division, Nova Polymers offers the materials, technology, and support you need to compete at the highest level.

Discover why industry leaders choose Nova Polymers for their ADA signage manufacturing. Join the community of Preferred Fabricators who rely on our patented photopolymer technology to deliver consistent, clean, and reliable results—every single time.

Contact Nova Polymers today and experience the difference that 35+ years of photopolymer innovation can make in your ADA signage production.