Ensuring ADA compliance is essential for all signage fabricators and manufacturers. However, it’s not uncommon for certain details, such as the Stouffer Scale, to slip your mind from time to time. One of the most common mistakes in photopolymer production is neglecting to use the Stouffer Scale to ensure that bulbs are working properly. This might seem like a minor detail, but it makes all the difference. Poor exposure can lead to non-compliance, costly remakes, and a loss of customer confidence.

What is the Stouffer Scale?

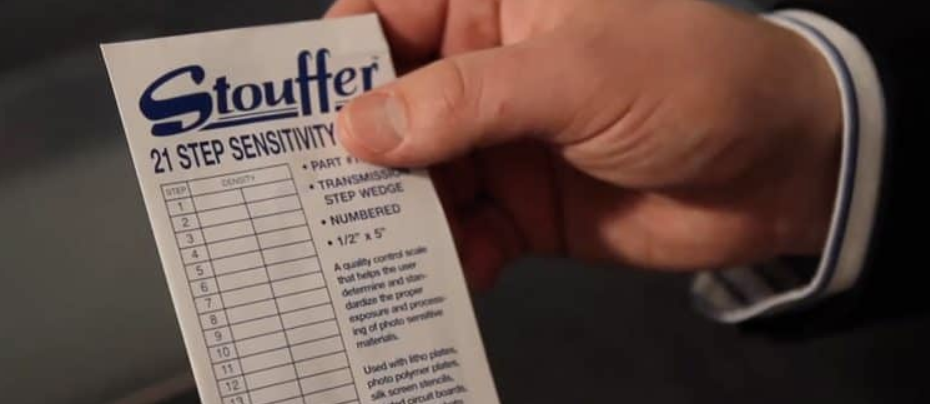

The Stouffer Scale is a small strip of reusable film negative with a series of numbers ranging from 1 to 21. Each number is encompassed in a block that displays different grayscale tones, from clear to light gray to black. The Stouffer Scale is considered the “holy grail” of photopolymer processing because it ensures that photopolymer has been exposed properly with the correct shoulders, thus ensuring ADA compliance. Like any film negative, the Stouffer Scale reacts to UV light. Continued use of the Stouffer Scale results in lower opacities, which can cause false readings.

The Stouffer Scale measures the UV output from the bulbs, allowing you to determine when to increase the exposure time to maintain the proper shoulder on the photopolymer. Depending on the results, fabricators can ascertain whether they need to adjust the UV output by increasing exposure time or replacing their bulbs. Regularly using the Stouffer Scale is essential to ensure your bulbs are functioning optimally, so fabricators must check it on a weekly basis and keep a record of the results in a production log.

Understanding Measurements with the Stouffer Scale

The Stouffer Scale reads different measurements for each type of photopolymer material used; there is no general fixed value to pinpoint. Each material has its ideal value to determine whether it is properly exposed to the right amount of UV light:

- For EX materials, the scale should read 12-13.

- For PT materials, the scale should read 15-16.

It’s crucial for fabricators to know how to read the Stouffer Scale accurately. Ensure you read it based on the last exposed number, as that indicates the current UV output from your bulbs. Do not consider partial reads. If the intended exposed number is not reached, you must adjust the exposure time or replace your bulbs.

Shelf Life of the Stouffer Scale

The Stouffer Scale has a shelf life of 1 to 3 years, depending on its usage. Its photoreactive nature can change over time, so a scale that has been in storage for more than three years may not yield reliable results. If you regularly use the same scale, it’s advisable to replace it every six months to one year to ensure accurate results.

Although acquiring a new scale may seem like a hassle, it allows you to create ADA-compliant signage continuously. Regularly using the same scale can lead to mistakes in compliance and exposure, resulting in significant issues. Consider partnering with a signage manufacturer that can provide a new scale annually, which helps reduce costs while ensuring you always use the most up-to-date equipment.

How to Use the Stouffer Scale

Wondering how to use the Stouffer Scale effectively? Follow these eight easy steps to achieve ADA compliance:

- Place the Stouffer Scale on the surface of the photopolymer next to a film negative to show the relationship between the exposure and the shoulder of the photopolymer.

- Position the Stouffer Scale emulsion side down for accurate readings.

- Center both the photopolymer and the Stouffer Scale in the machine.

- Ensure a proper vacuum and close the drawer to start the exposure process.

- Once exposure ends, open the drawer and roll back the vacuum sheet.

- Initiate the washout process.

- After washing, place the sheet in the dryer.

- Once drying and post-exposure are complete, check the results. Anything under a solid 15 to 16 indicates that more UV exposure is needed; over 16 suggests exposure can be reduced.

Maintaining the Quality of Your Stouffer Scale

While the Stouffer Scale is a simple tool, keeping track of its usage and wear can become confusing. Fabricators should monitor how well their Stouffer Scale is performing by maintaining a photopolymer production log. This log should include all key items such as dates, job numbers, materials processed, lot numbers, exposure times, washout times, wash temperatures, drying temperatures, post-exposure times, and UV scale readings. Keeping track of these factors will help determine how much the scale has been used and when it’s time for a replacement. This log not only provides clear information on the usage of the Stouffer Scale but also helps ensure the production of ADA-compliant signage.

Key Takeaways

ADA compliance is a critical objective for all signage manufacturers and fabricators. Although various tools and equipment can assist in achieving compliance, there is no more reliable ally than the Stouffer Scale. Businesses should take the time to evaluate their current workflow processes to ensure adherence to ADA specifications. Those who effectively utilize the Stouffer Scale will not only maintain compliance but also consistently produce high-quality signage.

At Nova Polymers, we offer custom solutions that include all the tools you need to ensure ADA compliance. For more information on our services, reach out to us today.