The signage design and fabrication world continues to evolve as ADA regulations remain central to ensuring accessibility. Since introducing the 2010 ADA Standard for Accessible Design, sign makers have been focused on meeting these standards, particularly when producing ADA compliant braille signage. Keeping up with these regulations and technological advancements remains essential for maintaining compliance and ensuring inclusivity.

The Evolution of ADA Compliant Braille Standards

The 2010 ADA Standard for Accessible Design, which went into effect on March 15, 2012, was the first major update to ADA regulations since the early 1990s. This update closely aligns with the 2004 ADA Accessibility Guidelines (ADAAG), bridging the gap between state and federal regulations for ADA-compliant features, including braille signage.

Although the 2010 Standard did not introduce entirely new regulations for ADA compliant braille, it refined key aspects of the guidelines, such as sign mounting height and character spacing, directly affecting how braille is designed and produced. In 2024, these guidelines remain as relevant as ever, ensuring accessible signage consistently produced according to federal standards.

The Role of Photopolymer in ADA Compliant Braille

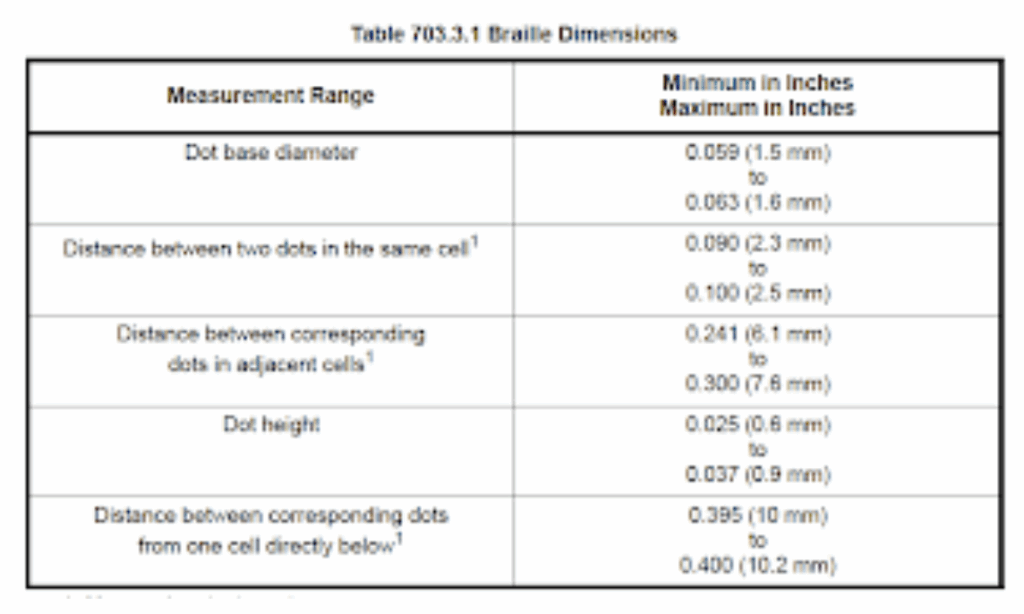

A critical aspect of ADA-compliant signage is ensuring the braille on these signs meets specific size and shape requirements. Section 703.3.1 of the ADA Standards specifies: “Braille dots shall have a domed or rounded shape and shall comply with Table 703.3.1.”

Photopolymer materials are an excellent choice to meet these specifications. At Nova, we continue to use photopolymer substrates to produce ADA-compliant braille. Our products, including the NovAcryl line, are designed with precision to ensure braille dots are accurately domed or rounded, ensuring compliance with ADA requirements.

Creating ADA Compliant Braille with Photopolymer

In 2024, the process for producing ADA compliant braille signage using photopolymer substrates remains focused on precision and consistency. There are four essential steps:

- Artwork Design: Using our Workflow Manager (WM) software, we ensure that the Braille dot size is reduced to .044 inches during exposure, creating the necessary shoulder for proper dot formation. WM software adheres to ADA guidelines for character size, placement, and fonts, ensuring that all signage is compliant.

- Film Generation: We generate high-density film negatives using the latest InkStar Film Solution technology. This film allows for the proper exposure of the photopolymer, ensuring accuracy in the final product.

- Photopolymer Processing: Consistency in UV exposure is critical for ADA-compliant braille. Using a 21-step Stouffer Scale, we measure exposure levels to maintain the proper size and shape of braille dots. By ensuring consistent UV output, we guarantee high-quality ADA-compliant signage.

- Finishing: After processing, we apply the appropriate topcoat. This could be a paint coating for surface-decorated signs, while sub-surface decorated signs receive a clear coat. With our partnership with Matthews Paint, we ensure that all final coatings meet the required specifications for durability and appearance, creating perfectly domed braille dots.

Keeping Up with Changes: ADA Compliant Braille in 2024

Though the 2010 ADA Standard remains unchanged, there has been growing awareness and education about accessibility in the built environment. In 2024, new tools, resources, and educational opportunities will help sign fabricators and designers stay compliant and updated with evolving best practices.

Nova Polymers continues to provide essential resources for sign fabricators, including training programs and webinars that explore ADA compliance. Although misinformation still exists in some areas of the industry, our commitment to accurate education ensures that our clients can confidently produce ADA-compliant braille signage.

We also offer an AIA Continuing Education course titled “ADA Requirements for Room Identification Signs.” This course covers the essentials of ADA compliant braille, helping sign makers stay compliant and informed in this evolving space.

Additional Resources for ADA Compliant Braille

- Watch a Video on How to Process Photopolymer

- Watch a Video on How to Use the 21-Step Stouffer Scale

- View and Download the 2010 ADA Standard for Accessible Design

- Visit the DOJ ADA Home Page

Looking Forward: Stay Informed and Compliant

As the demand for accessible environments grows, it’s more important than ever for sign designers and fabricators to stay informed about ADA compliant braille. Nova Polymers continues to provide the resources and tools necessary to ensure compliance and excellence in braille signage production.

Stay tuned for our upcoming webinar series, which will cover ADA requirements in depth and provide essential insights into ADA-compliant braille.

Contact us today for more information or to register for our educational programs.